SPARE PARTS

Home | SPARE PARTS

In today’s fast-paced industrial sector, reducing the downtime of equipment is crucial to maintaining productivity, meeting deadlines, and maximizing profits. This can be achieved by implementing strategies to reduce maintenance expenses and ensuring the availability of spare parts when necessary.

One key strategy to reducing downtime is to minimize maintenance expenses. This can be achieved by implementing preventative maintenance practices, regularly servicing equipment, and investing in high-quality, durable machinery. By reducing the need for repairs and minimizing downtime, businesses can increase productivity, reduce costs, and improve overall efficiency.

Another important strategy is to ensure the availability of spare parts when necessary. This can be achieved by establishing relationships with reliable suppliers who can quickly and efficiently deliver high-priority spare parts when needed. Having a trustful stock of spare parts on hand can help businesses minimize downtime, reduce costs associated with emergency repairs, and increase overall efficiency.

Additionally, providing support for manufacturing, supplying, and replacing spare parts in a factory is essential for maintaining productivity and minimizing downtime. This can include partnering with experienced and reliable suppliers who can quickly provide customized solutions to meet specific needs, ensuring that spare parts are readily available when needed, and providing ongoing technical support to help businesses maximize the efficiency of their equipment.

Moreover, ensuring the availability of high-priority spare parts is another key strategy to reduce downtime. This can be achieved by conducting regular maintenance checks, identifying potential issues early on, and having a reliable stock of high-priority spare parts on hand. By prioritizing the availability of these spare parts, businesses can reduce downtime, minimize production loss, and increase overall efficiency.

In conclusion, minimizing downtime and reducing maintenance expenses are essential for businesses to remain competitive and achieve long-term success in the industrial sector. By implementing strategies such as preventative maintenance, investing in high-quality equipment, establishing relationships with reliable suppliers, and ensuring the availability of high-priority spare parts, businesses can increase productivity, reduce costs, and improve overall efficiency.

-Reducing the Down Time of Equipment. -Reducing Maintenance Expenses. -Paying Less, Earning More.(Trustful Stock in your Factory) -Support for Manufacturing, Supplying and Replacing of Spare Parts in Your Factory. -Ensuring the Availability of High Priority Spare Parts When Necessary.

Pre-Heating System

A ceramic bush is a type of bushing or bearing made from ceramic materials. It is used in a variety of applications where high wear […]

Mass Flow Meter

Axial Piston Pumps are hydraulic pumps that use a series of pistons arranged in a circular pattern around a central drive shaft to generate […]

SCREW PUMP

The filter is made up of multiple layers of cotton gauze material that are oiled to create a barrier against dirt, dust, and other airborne […]

New Technology for Defect-less Mixing Head

One new technology for defect-less mixing head is the use of ultrasound waves to monitor and control the mixing process. This technology involves embedding ultrasonic […]

PLC Card

The manual Split Edge Filter is a type of filtration system used in the polyurethane industry to remove impurities and debris from the raw materials […]

Barrier Relay

The manual Split Edge Filter is a type of filtration system used in the polyurethane industry to remove impurities and debris from the raw materials […]

Axial PISTON PUMP

The filter is made up of multiple layers of cotton gauze material that are oiled to create a barrier against dirt, dust, and other airborne […]

Gear PUMP

The filter is made up of multiple layers of cotton gauze material that are oiled to create a barrier against dirt, dust, and other airborne […]

Pressure Transmiter

Axial Piston Pumps are hydraulic pumps that use a series of pistons arranged in a circular pattern around a central drive shaft to generate […]

Level Transmiter

Axial Piston Pumps are hydraulic pumps that use a series of pistons arranged in a circular pattern around a central drive shaft to generate […]

MAGNETIC COUPLING

A Sonotrode is a critical component of an Ultrasonic Tube Welder. It is a tool that generates high-frequency vibrations which are used to join thermoplastic […]

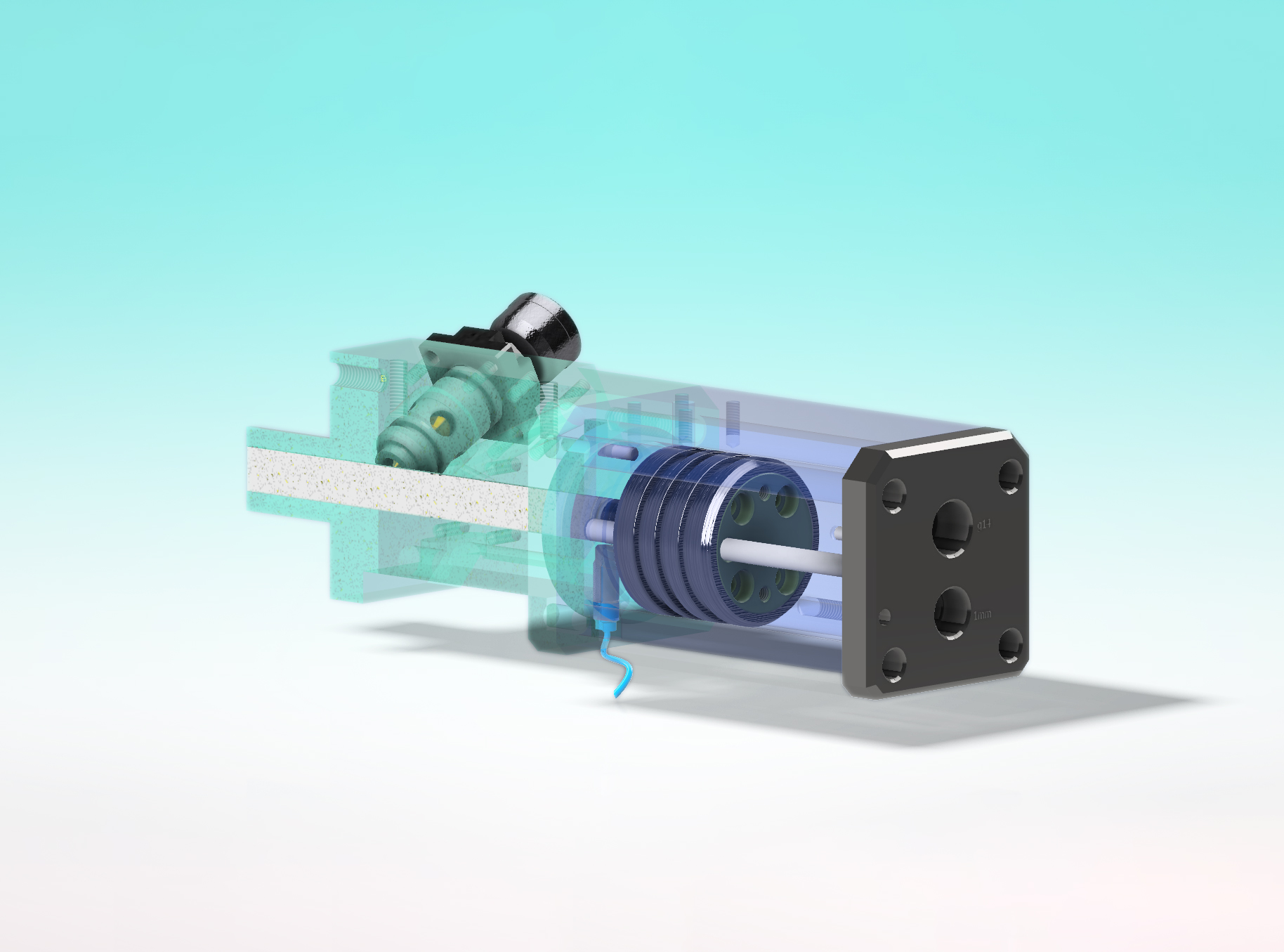

MIXING HEAD

A Sonotrode is a critical component of an Ultrasonic Tube Welder. It is a tool that generates high-frequency vibrations which are used to join thermoplastic […]

SONOTRODE ANVIL

A Sonotrode is a critical component of an Ultrasonic Tube Welder. It is a tool that generates high-frequency vibrations which are used to join thermoplastic […]

AXIAL PUMP PARTS

A Sonotrode is a critical component of an Ultrasonic Tube Welder. It is a tool that generates high-frequency vibrations which are used to join thermoplastic […]

Just complete the enquiry form, we will get back to you in 24 hours.