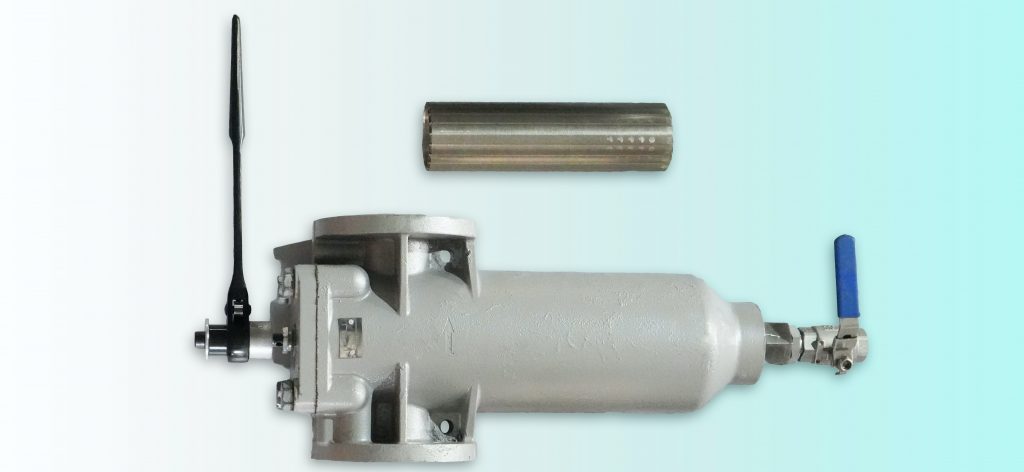

The manual Split Edge Filter is a type of filtration system used in the polyurethane industry to remove impurities and debris from the raw materials before they are processed into polyurethane products. The filter consists of a cylindrical housing that contains a series of pleated filter elements, which are designed to trap particles and prevent them from entering the polyurethane production process.

“ Based on years of experience and optimization in production lines, our company has produced this product for the first time. For more information, you can contact us through the inquiry form ”

K-Factor Team

In the polyurethane industry, the Split Edge Filter is typically used in the production of high-quality polyurethane foam products such as furniture, bedding, and automotive components. By removing impurities and debris from the raw materials, the filter helps to ensure that the final products meet strict quality standards and have consistent performance characteristics.